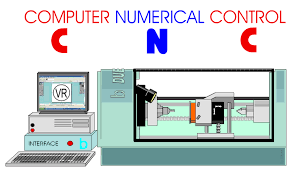

Introduction to Computer Numerical Control (CNC)

Imagine a world where precision meets automation. Welcome to the realm of Computer Numerical Control, or CNC for short. This technology revolutionized manufacturing and design processes by enabling machines to perform tasks with unmatched accuracy. From intricate engravings on jewelry to heavy-duty machining in aerospace, CNC plays a crucial role across various sectors.

As we dive deeper into this fascinating topic, you’ll discover the diverse industries harnessing the power of CNC technology and how it benefits them immensely. Whether you’re an enthusiast eager to learn or a professional seeking insights, understanding who uses Computer Numerical Control is essential in today’s tech-driven landscape. Let’s explore!

Industries that Utilize CNC Technology

Computer Numerical Control technology has carved a niche across various sectors. One prominent industry is aerospace, where precision is critical for safety and functionality. CNC machines produce intricate parts like turbine blades with remarkable accuracy.

Another sector benefiting from CNC is automotive manufacturing. Here, components such as engine blocks and chassis are crafted efficiently. The ability to work with different materials enhances the production process.

The medical field also relies on CNC technology for devices like prosthetics and surgical instruments. Customization plays a vital role in meeting patient-specific needs.

Furniture design manufacturers utilize CNC routers to create unique patterns and shapes in woodwork. This enables artisans to blend creativity with precision effortlessly.

Electronics industries depend on CNC machines for circuit board fabrication, ensuring high-quality assembly of complex electronic devices. Each application highlights the versatility of Computer Numerical Control technology in modern manufacturing processes.

Benefits of Using CNC Machines

CNC machines streamline production processes with incredible precision. They eliminate human error, ensuring consistent quality in every product manufactured.

Another advantage is the speed at which CNC machines operate. Automated systems can work continuously without fatigue, significantly boosting productivity compared to manual methods.

Flexibility is another key benefit. CNC technology can easily adapt to different materials and designs, making it suitable for various industries—from aerospace to woodworking.

Additionally, using CNC machines reduces waste. The software optimizes cutting paths and material usage, saving resources and lowering costs.

Safety also improves in environments utilizing CNC technology. Operators are less exposed to dangerous tools since most tasks are automated, creating a safer workspace overall.

These benefits make Computer Numerical Control indispensable for modern manufacturing practices across various sectors.

Popular Types of CNC Machines

CNC machines come in various types, each designed for specific tasks. The most common is the CNC milling machine. It uses rotary cutters to shape materials into precise designs and can create complex geometries.

Another popular type is the CNC lathe. This machine rotates the workpiece against a cutting tool, allowing for cylindrical shapes and detailed finishes. It’s ideal for producing shafts, bolts, and other round components.

Plasma cutting machines are also noteworthy. They use high-velocity jets of ionized gas to cut through metal sheets with precision. This method is favored in industries requiring quick and clean cuts.

Then there are laser cutters that utilize focused light beams to slice through materials like wood, metal, or acrylic with astonishing accuracy. Their versatility makes them suitable for both intricate designs and mass production.

Lastly, 3D printers represent an exciting evolution in CNC technology by layering material to build three-dimensional objects from digital models.

Advancements in CNC Technology

CNC technology has seen remarkable advancements in recent years. One significant improvement is the integration of artificial intelligence and machine learning. These innovations enable machines to learn from past operations, enhancing precision and efficiency.

Another area of progress is automation. Automated CNC systems can now run unattended for extended periods, drastically increasing productivity. This allows manufacturers to focus on other critical tasks while their machines work seamlessly.

Improved software solutions have also emerged, making programming easier and more intuitive than ever before. User-friendly interfaces allow operators with different skill levels to create intricate designs without extensive training.

Additionally, 3D printing capabilities are being incorporated into CNC processes. This combination opens new possibilities for prototyping and production methods that were previously unimaginable. As these technologies evolve, so too does the landscape of manufacturing across various sectors.

Training and Education for CNC Operators

Training for CNC operators is vital to ensure they can effectively manage these advanced machines. Programs are available at various levels, from community colleges to specialized technical schools.

Hands-on experience is crucial. Many institutions offer labs where students can work directly with CNC machinery, enhancing their practical skills. These programs often cover programming languages like G-code and M-code, which are essential for operating CNC machines.

Certifications also play a significant role in career advancement. Obtaining credentials from recognized organizations boosts credibility and job prospects in the competitive manufacturing industry.

Online courses have gained popularity as well, providing flexibility for those already working or with other commitments. Virtual simulations allow learners to practice without the risks associated with real equipment.

Networking opportunities through workshops and industry events help aspiring operators connect with experienced professionals while staying updated on advancements in technology and best practices.

Future Outlook for the Use of CNC

The future of Computer Numerical Control (CNC) is bright and full of possibilities. As industries evolve, so does the demand for precision and efficiency in manufacturing processes.

Emerging technologies like artificial intelligence and machine learning are set to enhance CNC capabilities. These advancements will enable machines to learn from their past operations, optimizing performance over time.

Moreover, the integration of Internet of Things (IoT) technology promises real-time monitoring and data analytics. This connectivity allows manufacturers to track production metrics seamlessly.

Sustainability also plays a crucial role in future developments. Eco-friendly materials and energy-efficient practices are becoming standard expectations within CNC applications.

As more sectors recognize these benefits, the adoption rate will likely soar, leading to innovation that we can only begin to imagine today. The landscape is shifting quickly, positioning CNC as a cornerstone of modern manufacturing solutions for years ahead.

Conclusion

Computer Numerical Control technology stands at the forefront of modern manufacturing and design. Its influence spans various industries, from aerospace to automotive, showcasing its versatility and efficiency. The advantages it brings—precision, reduced labor costs, and increased productivity—make it an invaluable tool for businesses aiming to stay competitive.

As CNC machines continue to evolve with technological advancements like automation and AI integration, their applications are likely to expand even further. This evolution promises new opportunities for innovation across sectors.

For those interested in entering this field or advancing their skills, numerous training programs cater specifically to aspiring CNC operators. As demand grows for skilled professionals adept in using these machines, pursuing education can lead to rewarding career paths.

The future of Computer Numerical Control appears bright as industries embrace its capabilities. With ongoing developments shaping how we manufacture goods today and tomorrow, investing time into understanding CNC technology might just be the key to unlocking potential breakthroughs within your industry or project.